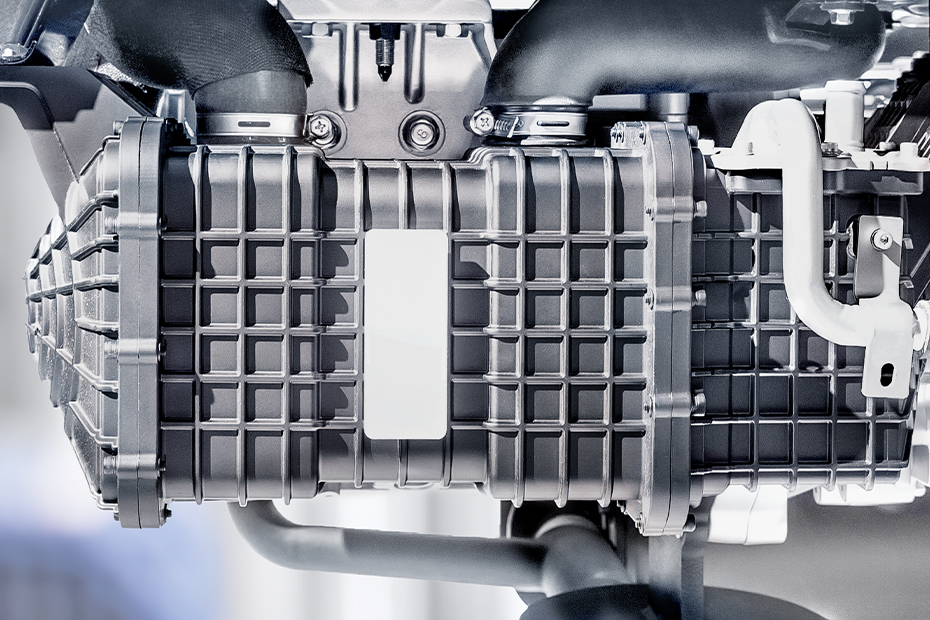

Sealing fuel cell and electrolyser stacks as well as redox flow batteries has until now required individual moulds and discontinuous manufacturing. A new process from Laufenberg and Wevo permits the continuous production of flat gaskets – significantly increasing manufacturing efficiency for hydrogen and battery components.

THE PROCESS AT A GLANCE

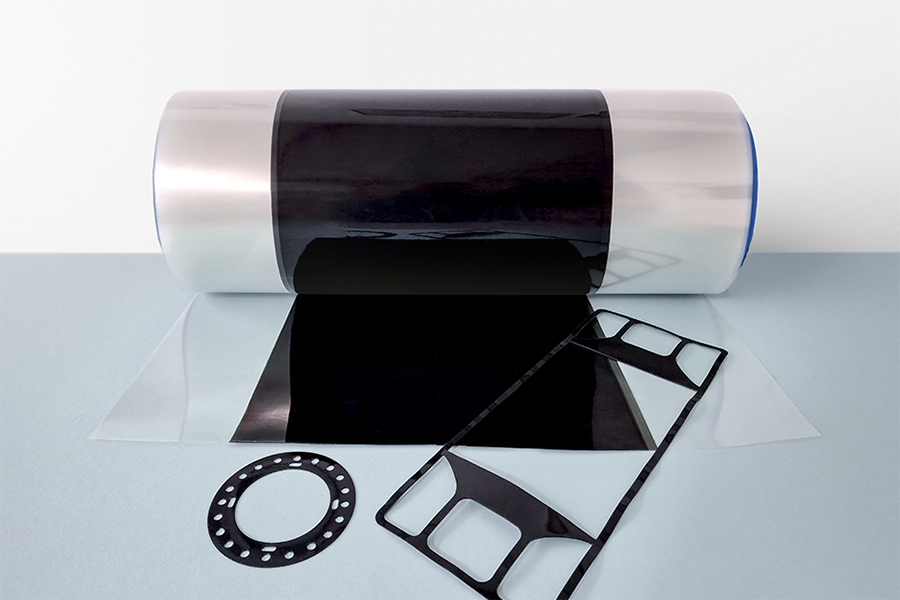

Wevo’s specially developed two-component elastomers are mixed and applied in liquid form to a carrier film using Laufenberg’s coating equipment. Coating takes place in a roll-to-roll process and can be applied on one or both sides.

Curing takes place in a multi-zone tunnel oven, with the temperature of each zone individually adjustable to the material. Optional pre-curing using infrared (IR) emitters shortens the curing time and removes any air bubbles. Line speeds from 0.5 to 50 m/min allow flexible scaling. Customers receive the tack-free, fully cured material either as a roll or as precision-cut gaskets.

With this technique, layer thicknesses from 20 µm to 2 mm can be achieved for pure elastomer gaskets. Combined with carrier films, hybrid seals with a total thickness from 70 µm to up to 4 mm – depending on the core carrier – can be produced. This makes it possible to manufacture both very thin and highly durable seals.

CHOICE OF CARRIER FILM AND ELASTOMER

The choice of elastomer and carrier film depends on the type of electrolyser, fuel cell or redox flow battery. Here, manufacturers of fuel cells and electrolyser stacks benefit from the many years of expertise of both of companies.

Laufenberg contributes its know-how in coating silicone materials. Where a pure elastomer seal is required, a carrier film is selected that can be removed after the curing of the Wevo material. Alternatively, the carrier film remains in place to produce a hybrid seal. This is advantageous, for example, with very soft sealants, to enhance dimensional stability and pressure resistance.

Wevo has been developing special silicones and modified polyurethanes with low hydrogen permeation for many years. These are already used successfully as liquid sealants and adhesives in fuel cells and electrolyser stacks. Application has typically involved dispensing sealing beads on to bipolar plates or flow frames using screen-printing or dispensing. The process developed jointly with Laufenberg now enables the production of prefabricated gaskets in a roll-to-roll process. Pot life, curing time and other material properties are specially adjusted and can be individually adapted upon request.

MEET THE EXPERTS

Wevo will be exhibiting at hy-fcell in Stuttgart from 7–8 October, while Laufenberg will be at the Hydrogen Technology Expo in Hamburg from 21–23 October. Experts from both companies will answer questions on the new process, material selection and process integration.