To achieve higher performance and new functionalities for traction batteries and power electronics, increasingly specialised high-performance adhesives are being used. The new addition-curing RTV silicone from Wevo – WEVOSIL 28015 FL – has been tested in practical applications together with customers and meets the high demands of industry with particular precision. Key technical properties at a glance:

- Thermal conductivity: 1.5 W/m·K (measured according to DIN EN ISO 22007-2:2015-12, hot-disk method) – ensures targeted heat dissipation even at high power densities

- Wide operating temperature range: high stability up to 200 °C, very good flexibility down to −60 °C – for reliable performance under extreme environmental conditions

- Mechanical properties: Shore A 70, high modulus of elasticity (60 N/mm²) – for structural bonding with high stability

- Residual flexibility: elongation at break 20–25 % – compensates for stresses and prevents cracking during temperature changes

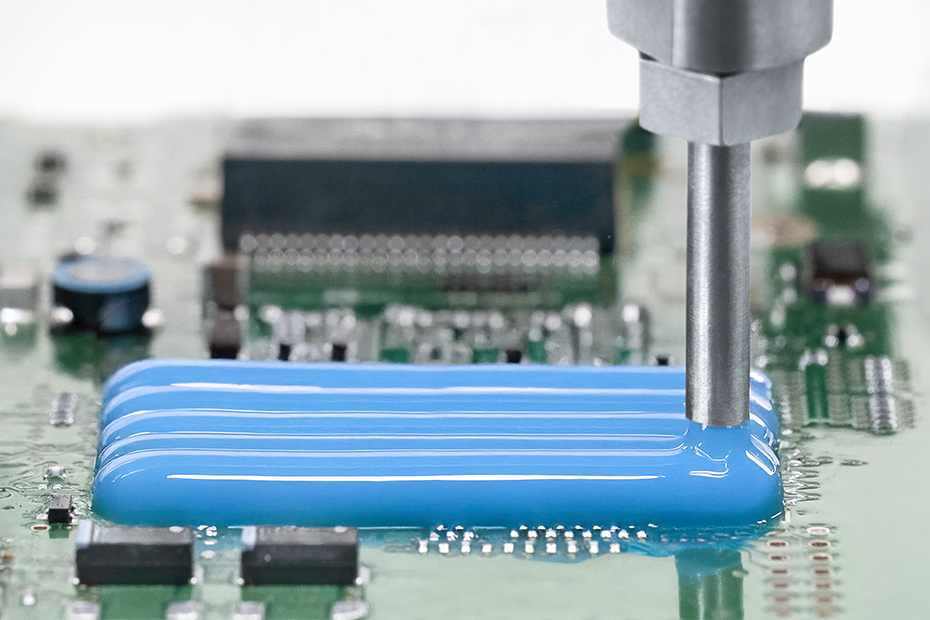

- Easy application: thixotropic material for bead dispensing from cartridges, hobbocks or drums – for CIPG and FIPG (cured- and formed-in-place gasket) applications as well as flexible, efficient production processes

- Fast curing: initial adhesion > 2 MPa within minutes by infrared (IR) or laser curing – enables fast further processing

- Process reliability: addition-curing system – prevents shrinkage and gap formation for reliable bonding even in closed components or housings

Silicone adhesive for EV batteries

In electric vehicles, battery modules are increasingly taking on load-bearing functions in the bodywork. They must ensure crash safety, thermal resistance and mechanical stability. With its high Shore hardness and modulus of elasticity, WEVOSIL 28015 FL, as a silicone for the automotive industry, ensures stable structural bonding of the modules to the housing or adjacent components. At the same time, the adhesive ensures reliable thermal connection – for example, to the cooling system or the bodywork, which is often used as a heat exchanger.

The result: high resilience of the battery modules to extreme temperature changes, such as those occurring during high acceleration, at the same time dissipating heat in a targeted manner. Additionally, efficient processing is ensured – the rapid curing of the RTV silicone by IR or laser contributes significantly here: It shortens process times and enables easy integration into highly automated production lines.

Reliable power electronics with structural adhesive from Wevo

In power electronics, chips and circuit boards with high power density must be cooled. Thermally conductive gap fillers and pastes used to date do not provide sufficient mechanical stability, meaning that additional screw connections or fastenings are required. This often results in complex sandwich constructions. The new thermally conductive structural adhesive from Wevo reduces process complexity by combining the required properties. This also ensures the long-term reliable operation of sensitive electronic components.

RTV silicones for technological progress

With WEVOSIL 28015 FL, Wevo emphasises its expertise in developing customised silicone systems that support technological progress in industries such as automotive and power electronics.